Personal Note: This article builds on hundreds of hours of research I did in 2021-2022 on the history of industrialization, technology, and productivity. While I published several successful articles as a result (i.e., In 1911, A Genius Revealed A Forgotten Science Of How To Be 50x More Productive Without Working More Hours), a centerpiece of the research remained unpublished.

I didn’t think anything of it until I noticed that the research was deeply informing how I made sense of AI. So, in this article, I share what I learned and apply it to AI in order to help your sense-making.

I don’t present conclusions. Rather, I present a transformative mental model that will help you form your own. Mental models help us do our own independent, deep thinking and not count on polarized Twitter hot takes or sensationalized media headlines.

Also, for the first time, I use historical fiction based on real events to communicate deeper ideas. I’m enjoying experimenting and growing my skill set as a writer. Let me know what you think of this format! Do you like the story or do you find it distracting?

On a June afternoon in 1752, the skies over Philadelphia loomed dark and electric.

Everyone ran indoors to seek shelter. Nearly everyone, that is.

“It’s time,” a 46-year-old Benjamin Franklin told his son.

The moment they had been waiting for had arrived. It was exciting and terrifying.

Together, they stepped into the vast openness of a field. In Franklin's hands was a makeshift contraption – a rudimentary kite, crafted from a silk handkerchief stretched taut over a cedar cross. From its pinnacle hung a wire from which a solitary key dangled.

As they released the kite, the wind seized it, hurtling it into sky. Franklin’s gaze never wavered from the key, his anticipation a palpable force in the electric air.

Eventually, as the clouds retreated in the wake of the storm, the pair reeled the kite back.

And then it happened.

As Franklin reached out, his knuckles inching towards the key, a spark leaped forth—a ghostly, ethereal visitor. It was a fleeting touch, but in that electric kiss lay the answer he had sought.

Eureka—the word echoed silently in Franklin’s mind.

The key’s timid spark was more than just a physical manifestation; it was a revelation.

In that charged moment, Benjamin Franklin had unraveled a truth: Lightning was indeed electrical.

This moment would help form the basis for further invention and experimentation that would lead to the electrification of the world.

Fast forward 127 years to an inventor who runs the next leg of the relay race and builds on humanity’s burgeoning scientific understanding of electricity…

A 36-Year-Old Inventor Creates The First Light Bulb For The Home

In Menlo Park, NJ on the night of October 21, 1879, something more than autumn's chill hung in the air.

Thomas Edison's workshop, a realm of dreams and relentless toil, was alive with a palpable, electric anticipation. The floors, lined with the ghosts of thousands of failed attempts, whispered secrets of persistence.

Edison, his face a mask of concentration and unyielding determination, stood among his team. His hands, those of a craftsman, a thinker, and a dreamer, hovered over their latest test—a bulb, fragile yet promising, harboring a carbonized thread filament.

"To success or to learning," Edison murmured, more to himself than to his team. His voice was a steady beacon in the sea of uncertainty that flooded the workshop.

His team, a motley crew of brilliant minds, watched with bated breath. There was Charles Batchelor, Edison's loyal right-hand man, his eyes reflecting a mix of skepticism and hope. Francis Upton, the mathematician, calculated odds silently in his mind.

Their eyes portrayed both excitement and weariness. All had spent the last year working around the clock in the race to build the first light bulb that would be ready for home use. Edison himself barely slept, often resting only briefly on the bed in his office.

The room held its breath as Edison connected the wires. The filament began to glow—first timidly, then with a steady, warm radiance that spread throughout the room.

"It's working," whispered one of the team members.

For hours, they watched the bulb, as if by sheer will they could keep it alight. It glowed on, defying past failures. In that moment, under its humble glow, the world shifted imperceptibly. What had been the realm of fantasy was now palpably real.

When the bulb finally dimmed and succumbed to the inevitable, it marked not an end but a beginning. The light had lasted 13.5 hours, a triumph in its own right.

As dawn broke, the world remained unaware of how it had changed that night in Menlo Park. Edison and his team stepped out of the workshop, the first witnesses to a new era, their shadows stretching long in the light of a new day. The age of electric light had begun, born from a blend of genius, madness, and an unyielding belief in the impossible.

Benjamin Franklin made an important scientific discovery in 1752. In 1878, Thomas Edison built on top of the known science to engineer a transformative, affordable mainstream product.

While the science and engineering continued to evolve in order to make electricity more reliable and affordable, entrepreneurs took steps to electrify the world.

Each step paved the way for the next…

Over the next 75 years, the world became electrified

Power plants were built.

Electric lines were installed to transport it.

Standards were fought over (i.e., AC vc DC).

Laws were passed.

Slowly, how factories worked was transformed from the ground up.

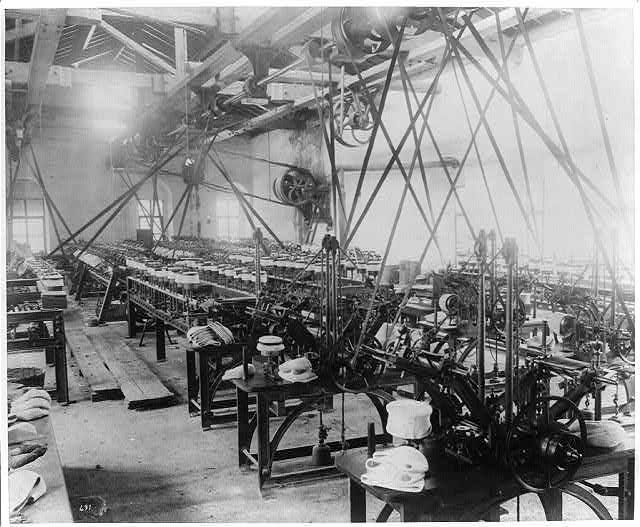

For example, the image below of an 1830 steam-powered cotton factory shows how the central axle led to a network of belts and gears.

MIT and Stanford researchers Andrew McAfee and Erik Brynjolfsson provide a great overview of how these factories worked in The Second Machine Age:

In a steam engine–driven plant, power was transmitted via a large central axle, which in turn drove a series of pulleys, gears, and smaller crankshafts. If the axle was too long the torsion involved would break it, so machines needed to be clustered near the main power source, with those requiring the most power positioned closest. Exploiting all three dimensions, industrial engineers put equipment on floors above and below the central steam engines to minimize the distances involved.

In his book, Electrifying America, historian David Nye explains why the machines needed to be near the central shaft. In one word, it was “friction.” The farther away from a central axle a machine was, the more belts and gears it needed. The more belts and gears it needed, the more friction there was, which lowered the efficiency of energy use.

Newer factories were designed with electric-first thinking.

For example, each machine could be connected to its own power source and put in the order of completion. Factories were one story instead of multiple stories

But, it wasn’t until 1913 that Henry Ford put everything together and launched modern manufacturing with the first automated assembly line.

So too were homes transformed.

Entrepreneurs across the world built electric-powered devices that transformed cooking, washing clothes, and much more.

The timeline below captures many of the major electrification milestones:

While it may not seem like it on the surface, the process of electrification can teach us a lot about the future of AI…

Introducing The Productivity Chain: A Tool To Predict The Future OF AI

The development of electricity went through several predictable stages over 200+ years:

Scientific Breakthrough

Engineering (General Purpose Technology)

Infrastructure Installation

Tool Creation

Adoption (Consumers, Businesses)

Reinvention

Or shown visually…

These stages build on one another and form a chain. A chain that leads to productivity and progress.

Furthermore, these steps don’t just exist in a vacuum. They exist in an environment that supports, constrains and directs its evolution…

Finally, Productivity Chains ALWAYS have side effects.

As I mention in Future Shock: This Is What Happens When Humans Can No Longer Adapt To The Modern World, According To Research, there is a predictable process that occurs which mitigates those side effects…

This is where things get interesting.

This chain doesn’t just exist for electricity. It exists for other General Purpose Technologies including AI.

Therefore, the model helps us understand how AI might play out.

But, before we jump into applying the model to AI, let’s do a deeper dive on each step so we can internalize the model…

Deep Dive: How The Productivity Chain Helps Us Understand The Evolution Of Major Technologies

Culture Of Innovation

When there is an innovation-friendly culture, inventors are rewarded for discovering and sharing new ideas. Therefore, more people find it worthwhile personally, socially, and financially to be innovative.

For most of human history, this did not exist. Being an inventor was punished.

Therefore, without the right culture, the scientific method was not practiced.

Given that innovation has been a norm throughout our lifetimes, it’s easy to take our culture for granted.

I learned about how new mindsets led to the scientific enlightenment from:

Improving Mindset: Economic historian Anton Howes on the significance of the Improving Mindset.

Optimism And Openness. Physicist David Deutsch is arguably the world’s #1 explainer of the scientific method. In his book, The Beginning Of Infinity, he explains how the scientific method words, and how it is underpinned by a culture of optimism and openness to novelty.

Stage #1: Scientific Breakthrough

All usefulness, every prediction, comes from understanding. However, if you no longer strive for fundamental explanations, but believe that it is sufficient to generate something useful, then you will merely move incrementally from one decimal place to the next, and even then, only in areas that are already well studied. This tendency has dramatically slowed down progress.

—David Deutsch

To get electrification took 150+ years of deeper scientific understanding of the phenomenon of electricity. For example, below are a few of the key scientific breakthroughs in the 18th and 19th centuries that set the stage:

1752: Demonstration that lightning was a form of electricity. [*]

1800: Voltaic pile creates means for continuous electrical current. [*]

1831: Understanding of mutual induction, a form of electromagnetic induction. [*]

1837: Mechanical generation of electricity. [*]

1883: Induction motor. [*]

1892: Nikola Tesla receives patents for polyphase AC electric power system.

I learned about the importance of science breakthroughs for overall economic productivity from Joel Mokyr, an economic historian who specializes in studying the precursors of the industrial revolution. Mokyr succinctly explains the significance of science to productivity in a paper where he talks about life before the industrial revolution:

People did not know enough about the physical world around them… Inventions in the pre-1700 era were the result of serendipitous strokes of luck, flashes of brilliant intuition, and above all experience, learning by doing, and the slow accumulation of incremental improvements of techniques in use. It was “a world of engineering without mechanics, iron-making without metallurgy, farming without soil science, mining without geology, water-power without hydraulics, dye-making without organic chemistry, and medical practice without microbiology and immunology.”

Technical progress in the eighteenth century slowly but certainly came to rely more and more on insights from natural philosophy, on a more useful mathematics, and on more careful experimental methods borrowed from scientific practice.

You can read deeper on this topic in Mokyr’s The Gifts of Athena: Historical Origins of the Knowledge Economy.

Stage #2: Engineering Of General Purpose Technologies (GPT)

Once we understood the science of electricity, it took another 100+ years of technological development:

1809: Sir Humphry Davy makes the first experimental arc lamp. [*]

1879: Thomas Edison and Joseph Swan independently invent usable consumer light bulbs. [*]

1879: The California Electric Company (now PG&E) is the first to use electrical power generators to supply multiple customers. [*]

1882: Edison sells electricity as a commodity. [*]

1883: Electric motors drive manufacturing machinery. [*]

1889: First electric power transmission line. [*]

1890s: Standardization of alternating current (AC) frequency [*]

1914: Establishment of electric utilities with central stations. [*]

1920: “Productivity growth eventually leapt in the 1920s.”[*]

I learned about the importance of General Purpose Technologies (GPTs) as critical input from a slew of researchers in a lineage that goes back 30 years:

Whole eras of technical progress and economic growth appear to be driven by … GPTs, [which are] characterized by pervasiveness (they are used as inputs by many downstream sectors), inherent potential for technical improvements, and “innovational complementarities,” meaning that the productivity of R&D in downstream sectors increases as a consequence of innovation in the GPT. Thus, as GPTs improve they spread throughout the economy, bringing about generalized productivity gains.

—Economists Timothy Bresnahan and Manuel Trajtenberg

In short, GPTs are defined by their pervasiveness, ability to improve over time, and capacity to lead to complementary new advances. [*]

Some of these breakthroughs are particularly important. They are General Purpose Technologies (GPTs) like:

Steam engine

Combustion engine

Electricity

Computer chips

Artificial intelligence

Stage #3: Infrastructure Installation

In her book, Technological Revolutions and Financial, researcher Carlota Perez explains the importance of this stage:

The new technologies will require the establishment of a whole network of interconnected services such as the specific infrastructure and the specialized suppliers, distribution channels, maintenance capabilities and others that provide the territorial externalities to facilitate diffusion.

Without roads, gasoline stations and mechanics, people cannot use automobiles, yet only enough automobiles on the road will make it profitable to run a station or a garage. So diffusion occurs through intricate feedback loops.

When it came to electricity, infrastructure installation included:

Power stations

Power lines

Electrical outlets

Standards

Stage #4: Tool Creation

With the electrical infrastructure in place, the next step was to actually find use cases for it.

While the uses are obvious in retrospect, they weren’t obvious at the time.

One of my favorite examples of this difficulty comes from historian Davide Nye’s Electrifying America:

Having electricity is one thing; knowing how to use it is another. To help people learn the new technology, REA [Rural Electrification Act] hired advisors like Louisan Mamer (1910-2005) from southern Illinois. For decades, Mamer and her colleagues traveled around the country staging what they referred to as an "electric circus." They taught people who had never used electricity how to operate and maintain equipment, cook and do household chores with electricity, and use the system safely.

But, eventually, use cases were found. Starting in the early 20th century, entrepreneurs built a wide variety of electric-powered tools:

1908: Electric vacuum cleaner

1911: Electric air conditioning

1913: Electric refrigerator

1913: Electric assembly line

1913: Electric dishwasher

1919: Pop-up automatic toaster

1935: Electric washing machine and dryer

With the creation of these tools, which became progressively cheaper, safer, capable, and more reliable, we saw their adoption by consumers and companies…

Stage #5: Adoption

It took all the way to the mid-20th century for America to become fully electrified:

1900: Less than 5% of mechanical drive power in American factories was coming from electric motors.[*]

1905: “By 1900, General Electric [the largest manufacturer of electric motors] had installed only 300 motors in 32 textile mills.” [*]

1930: 70% of households were electrified in the U.S.

Stage #6a: Management Reinvention

GPTs require investments in knowledge (skills, processes, equipment), which can lead to a fundamental rethinking of the organization of production.

What’s fascinating about this topic is the discontinuity between adoption and reinvention.

One would think that as soon as a transformative technology is released, it would change everything at a fundamental level overnight. But this just isn’t the case.

For example, put yourself in the shoes of a factory owner in 1900.

You spent a huge amount of money to set up your factory. You had to take out a large loan to buy:

A multistory factory building

A steam engine to power everything

Many custom-built machines

A network of belts and gears to connect the machines to the steam engine

Furthermore, you adopted time-tested assembly methods built on steam power assumptions. Things are working and your factory is profitable and you’re paying back investors and lenders.

Now, picture electricity arriving on the scene…

Adding lighting was easy, and, indeed, electric lightbulbs were adopted rapidly by factories en masse. Gas lamps simply had to be replaced with electric lightbulbs and light systems. And, this shift led to immediate gains that were easy to understand:

Machines could now be operated around the clock and machines didn’t have to sit idle

Fire insurance costs were less with dangerous gas lights removed

It was easier to do more intricate assembly work

The indoor air was healthier without gas lamps sucking out the oxygen

Sicknesses at the office decreased

In other words, factory owners used electricity to do what they were doing better.

Rebuilding the factory around electric energy was not so straightforward though. To fully adopt the electric paradigm would require:

Moving to a one-story building

Buying a new electric-power engine to replace the stream-powered engine

Buying all-new equipment

Also, consider that electricity was not yet as cheap, ever-present, or reliable.

So, what did factory owners do first?

Did they scrap everything and start from scratch? No.

After replacing the gas lamps with electric lightbulbs, they simply replaced the big steam engine in the center of the factory with an electric engine. All of the belts, gears, shafts, and machines remained unchanged.

This move also makes sense because large motors driving factories were more efficient than individual motors connected to individual machines. Researchers Andrew McAfee and Erik Brynjolfsson explain:

Perhaps unsurprisingly, records show that the electric motors did not lead to much of an improvement in performance. There might have been less smoke and a little less noise, but the new technology was not always reliable. Overall, productivity barely budged.

Therefore, you can’t really blame the delay of electrification in factories on old, stuck-in-their-way factory owners. Putting yourself in their shoes, would you have made a different decision? Probably not.

Thus, it is not surprising that the assembly line started where, when, and by whom it did in the 1910s. The car industry was a new, fast-growing industry without huge sunk costs into an old way of manufacturing. Henry Ford was a pioneering entrepreneur at the helm of a quickly growing startup. Furthermore, it wasn’t until the 1910s that electricity became affordable and reliable enough.

Thus, laying out machines in the order of the natural workflow of materials in one-story factories, what we call the assembly line, was not launched until 1913—more than 30 years after Edison invented the consumer lightbulb.

Stage #6b: Cultural Reinvention

Electrification showed up in the home, in businesses, and in cities creating a broad array of cultural transformations:

Days become longer (more things to do at night)

Suburban sprawl (electric pumps, refrigerator, washing machine)

Less time needed for household maintenance means more leisure time (vacuums, refrigerator, washing machine, stove, microwave, hair dryer, iron)

Rising standards of comfort and cleanliness (central air, washing machine)

More and faster entertainment/news options (radio, TV)

Cities become larger (subways, street cars)

New art forms made possible

Symbol of the positive power of technological progress and the arrival of modernity

Increased individualism (increase in appliances that can do work at home rather than via communal and commercial services)

Increased centralization of power

Summary: It’s one thing for me to explain the stages of the electricity Productivity Chain. It’s another to hear about it from one of the key figures who created it. In this rare and remastered 3-minute video clip, we hear about the electrification of the world from Thomas Edison himself.

In short, we needed four revolutions (scientific, technological, management, cultural) that occurred over 200 years for us to experience the huge productivity benefits of electricity. Furthermore, we can now understand why it took many decades for the productivity benefits of electricity to be fully realized after Edison invented the residential lightbulb.

Implication: Now that we have the Productivity Chain model fully fleshed out, we can use it to reason about the future of AI…